Maintain Temperature on TCM18 and TC1818 Heat Trace Controllers

Your How-To Guide on Maintain Temperature for TCM18 and TC1818 Heat Trace Controllers

Introduction

Welcome to our comprehensive knowledge base article dedicated to maintaining temperature with TCM18 and TC1818 heat trace controllers.

In this guide, we'll delve into the intricacies of maintaining temperature with TCM18 and TC1818 controllers, offering detailed insights and step-by-step instructions to help you achieve precise temperature regulation. Whether you're tasked with preserving critical process temperatures or preventing pipelines from freezing, this article will equip you with the knowledge and strategies needed to effectively maintain temperature control with confidence. Let's explore the world of temperature management with TCM18 and TC1818 controllers and elevate your heat tracing system to new levels of reliability and efficiency.

Step-By-Step: Changing Maintain Temperature

1. Enter Program Mode:

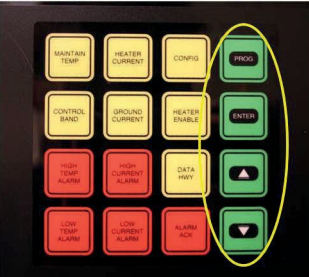

To program circuit control settings or control parameters, multiple keys in sequence

will need to be pressed. To change the settings associated with the

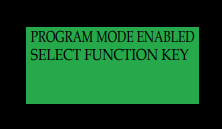

MAINTAIN TEMP key, first press the green PROG key.

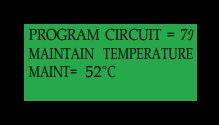

The Display now reads as shown :

2. Enter Maintain Temperature Setting

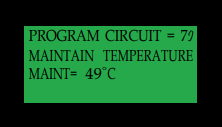

Press the MAINTAIN TEMP key.

The Display now reads as shown below with the flashing cursor I representing the

active data entry field:

3. Circuit Selection

Pressing the green UP or DOWN Arrow programming keys followed by the green

ENTER key allows the selection of the heat tracing circuit to program.

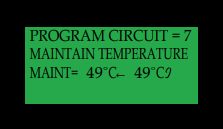

The display screen will now shift the cursor to the next value to program as shown

in the following display.

4. Changing Temperature Set Point

A single press of the green UP or DOWN arrow programming key will increase or

lower the Maintain Temperature set point by a single degree. Holding these keys

down will increase the indexing speed for cases where a significantly large increase

or decrease in set point is required. Once the new set point is reached, press the

green ENTER key to save the new set point.

The DISPLAY screen now appears as shown

The DISPLAY screen now appears as shown

At this point, pressing the green UP or DOWN arrow key will select the next heat

tracing circuit to program.

TIP: In many cases, the programmed value can be the same for a majority of heat

tracing circuits. Note that when sequencing through the circuit numbers, there is an

ALL option. This allows the programming of the same set point for all circuits on

this particular TCM18 module and permits only entering the set point once. When

selecting the ALL option, the values last programmed for ALL will initially appear as

a starting point for any value changes.

5. Exiting

When completed with this or any programming activity, press the green PROG key to exit and

return to SCAN MODE. However, if for some reason this is not done, the screen

will automatically return to SCAN mode operation after a short pause.

In industries where precise temperature control is paramount, TCM18 and TC1818 heat trace controllers play a pivotal role in ensuring operational success and product quality. This guide has provided comprehensive instructions for maintaining temperature with these controllers, offering detailed insights and step-by-step procedures to achieve optimal regulation. Whether preserving critical process temperatures or preventing pipeline freezing, the knowledge shared here equips users with the tools needed to confidently manage temperature control systems. By exploring the intricacies of temperature management with TCM18 and TC1818 controllers, users can elevate their heat tracing systems to new levels of reliability and efficiency.