ATCOM+ Programming Audit: Ensuring Optimal Heat Trace Controller Settings

Explore ATCOM+'s Programming Audit feature, an invaluable tool for detecting and rectifying deviations in heat trace controller settings. This guide will walk you through the importance of this function and how to utilize it

Efficiently managing your heat trace system requires precision and control over its various components. Deviations in controller settings can result in misoperations, undetected alarms, and unnecessary nuisance alerts. ATCOM+'s Programming Audit feature is your solution to these challenges. It's designed to meticulously scrutinize your heat trace controller settings and identify any discrepancies from the intended design parameters. In this guide, we'll explore how the Programming Audit feature can help you maintain the optimal performance of your heat trace infrastructure.

The Importance of Programming Audit:

The accurate and reliable performance of your heat trace system relies heavily on the settings programmed into your heat trace controllers. These settings ensure that the system activates when necessary, maintaining the desired temperature and preventing freezing or overheating. Deviations from these programmed parameters can have detrimental effects:

-

Incorrect Functionality: If controllers are not programmed correctly, they may not energize when required, leading to freezing or overheating of pipes or equipment.

-

Missed Alarms: An essential function of heat trace controllers is to raise alarms when temperatures deviate from the specified range. If controllers are incorrectly programmed, valid alarms may not trigger, leading to undetected issues.

-

Nuisance Alarms: Conversely, incorrect programming can also generate false alarms, diverting valuable resources to investigate non-issues.

Design settings are usually entered during the onboarding of ATCOM+ but if it's not, the controller's initial settings on the first import will be populated in the "Design Setting" section. So make sure these are reviewed or the system is commissioned correctly.

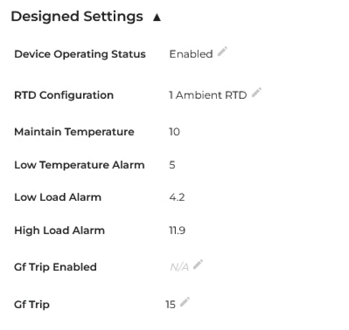

Setting the Stage: Design Settings

To ensure the Programming Audit feature works effectively, it's essential to start with the right foundation. ATCOM+ relies on the accurate entry of controller design settings. During the onboarding process, these settings are typically configured. However, if they're not, the initial settings upon the first import of data will populate the "Design Settings" section. Therefore, reviewing and verifying these settings is crucial to ensure your system's accuracy.

The Design setting typically comes from heat trace isometrics or setpoint schedules. But remember that sometimes these values are designed incorrectly and need to be changed.

Accessing the Programming Audit:

ATCOM+ offers two primary locations to access the Programming Audit feature:

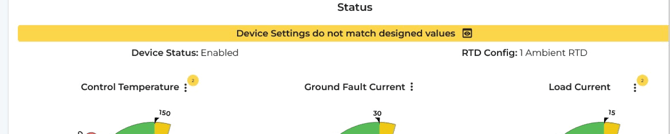

1. Device Monitoring Page:

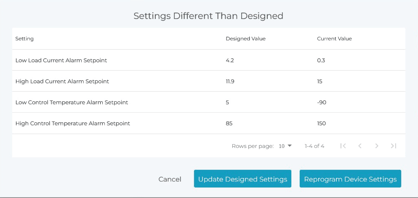

- On the Device Monitoring Page, users will notice an orange bar above the status bars when a programming deficiency is present.

- By clicking the orange bar, users can view specific programming discrepancies, including the current values and the designed values.

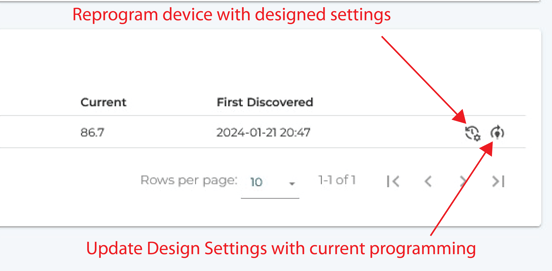

- Users have the option to reprogram the heat trace circuit or accept the existing programming and update the "Design Values" section.

- Note: This functionality is limited to administrators and EHT specialist users.

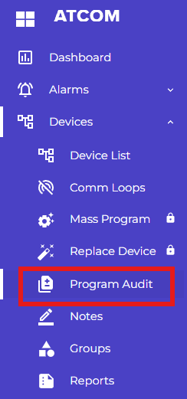

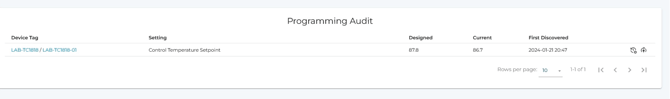

2. Programming Audit Section:

- This section provides an overview of all heat trace circuits with programming deficiencies.

- Users can sort circuits by unit or apply advanced filters for a more granular view.

- Within this section, users can reprogram the controller or update the "Design Settings" section to match the current settings effectively.

Conclusion: Ensuring Peak Performance

In summary, ATCOM+'s Programming Audit feature is your ally in maintaining optimal heat trace controller settings. By identifying and correcting deviations from design parameters, you'll enhance your system's efficiency, prevent missed alarms, and eliminate nuisance alerts. For an integrated and well-functioning heat trace infrastructure, regularly using the Programming Audit is a best practice that can't be overlooked.