Monitoring and Programming Heat Trace Controllers

The basics to monitoring and programming a heat trace circuit with ATCOM+

To effectively monitor and program a heat trace circuit in ATCOM+, it's important to start from the window or section where you want to access the specific circuit. For example, you might begin from the "Alarm Validation Screen" or the "Device List Screen." To ensure a seamless experience, right-click on the circuit you wish to monitor or program and open it in a new tab. This allows you to maintain your current context without losing your place.

On Opening - Retrieving Real-Time Data:

-

When you open a heat trace circuit in ATCOM+, the platform initiates the process of retrieving crucial data in real-time. This data includes the controller's alarm values, current readings, temperature sensor data, ground fault current, and all controller settings. While ATCOM+ continuously collects this data, monitoring a circuit takes precedence, and the data is retrieved immediately for user access.

-

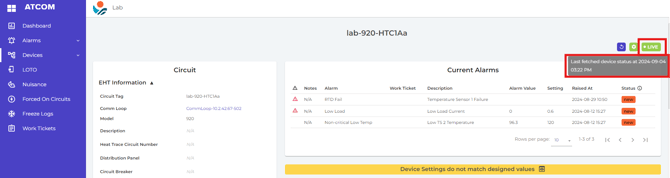

To verify if you have live data for the circuit, pay attention to the "LIVE" timestamp this acts as a status indicator

within the ATCOM+ interface (see screenshot). These indicators confirm the presence of real-time data.

within the ATCOM+ interface (see screenshot). These indicators confirm the presence of real-time data.

Ensuring Data Freshness:

- If you ever find yourself unsure about the freshness of the data displayed, there are a couple of actions you can take:

- Click the "Refresh" button

within the ATCOM+ interface.

within the ATCOM+ interface. - Alternatively, refresh your web browser to update the data.

- Click the "Refresh" button

Considerations for Data Retrieval:

-

It's essential to note that the speed of data retrieval can vary depending on factors such as the type of heat trace controller, communication protocol, and network status. For some older or legacy controllers that utilize ASCII communication protocols, the data retrieval process may take slightly longer, typically within the range of 10-15 seconds.

-

Patience is key when working with such controllers, as ATCOM+ efficiently gathers the necessary information, ensuring you have the most up-to-date data at your fingertips.

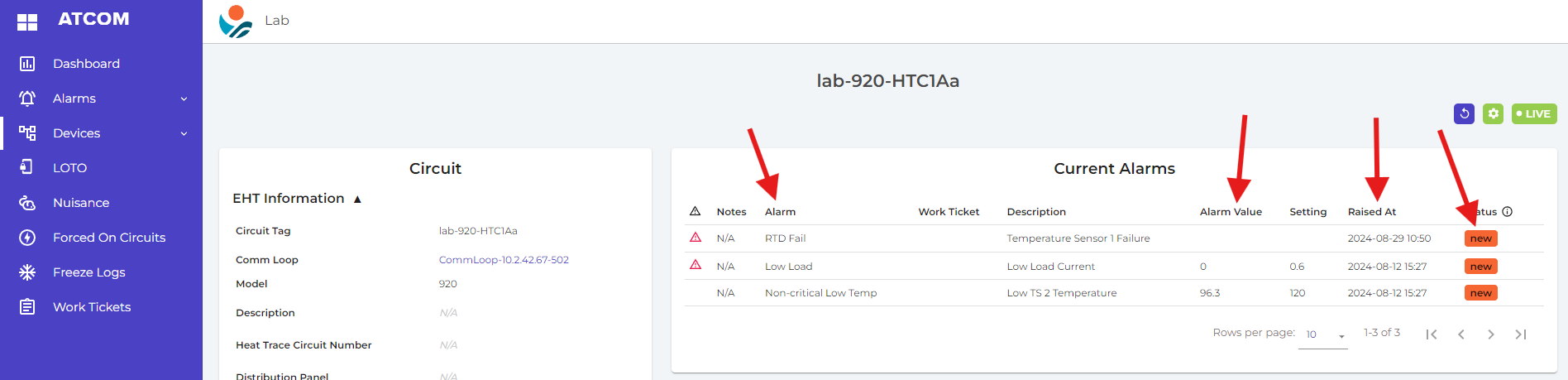

Monitoring Alarms in ATCOM+:

- In ATCOM+, the "Alarms" section is where you can conveniently monitor all alarms generated by the heat trace controller associated with the selected circuit. This section provides essential information regarding the alarms, including their specific alarm values and the live values associated with them. It's worth noting that these values may differ, especially in scenarios like low-temperature alarms where the alarm value typically reflects when the alarm was triggered and may not represent the current temperature status.

Understanding Alarm Status:

- ATCOM+ incorporates an "Alarm Status" section that serves to distinguish between new alarms and user-acknowledged alarms. These statuses are exclusive to ATCOM+ and provide a clear overview of alarm activity within the platform. It's important to clarify that acknowledging an alarm in ATCOM+ is distinct from acknowledging an alarm on a Thermon heat trace controller.

Resetting Alarms:

- The "Alarm Reset" button within ATCOM+ offers a valuable feature for users. By clicking this button, you can initiate the process of resetting an alarm directly within the associated heat trace controller. When you perform this action, several outcomes can occur:

- If the controller is no longer in alarm, the alarm will successfully reset, and the alarm status will clear.

- However, if the controller remains in alarm even after the reset, the alarm will reappear, and further actions may be required to address the underlying issue.

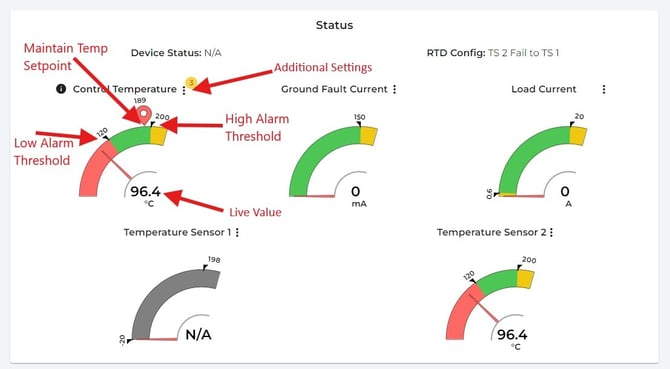

Circuit Status Section

- The "Circuit Status" section in ATCOM+ provides users with real-time insights into the health and performance of the selected heat trace circuit. This section displays a range of critical data, including live values, low and high threshold alarm settings, and the temperature maintain setting. This live data is vital for monitoring the circuit's operational status.

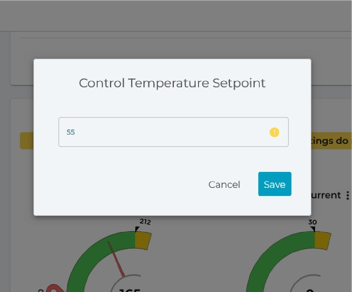

Basic Circuit Programming:

- Users with the appropriate permissions can conveniently modify the circuit's configurations directly from the Circuit Status section. By clicking on the low and high threshold values or the temperature maintain setting, you can easily adjust these parameters to align with your specific requirements. ATCOM+'s user-friendly interface empowers you to make basic programming changes effortlessly.

Advanced Controller Configurations:

- For more intricate adjustments and configurations, ATCOM+ offers an additional level of control accessible via the three dots

menu. The specific options available in this menu may vary depending on the model of the heat trace controller being monitored. Different controllers have varying programming capabilities, and ATCOM+ accommodates these differences seamlessly.

menu. The specific options available in this menu may vary depending on the model of the heat trace controller being monitored. Different controllers have varying programming capabilities, and ATCOM+ accommodates these differences seamlessly.

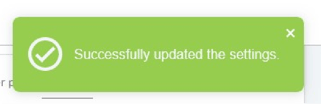

Confirmation of Programming Modifications:

- When users make programming modifications, ATCOM+ provides a clear and reassuring confirmation. A green indicator confirms that ATCOM+ has sent the write command to the controller and subsequently verified that the change has taken effect. This confirmation ensures that the programming adjustments have been successfully implemented.

If you encounter a communication error while making a programming modification, it can be caused by either a communication issue or ATCOM+ not retrieving the data promptly. In this situation, we recommend refreshing your browser to confirm whether the configuration was successful.

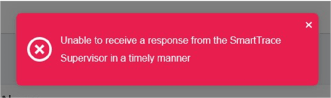

Controller Statistics and Trending:

This comprehensive suite of controller statistics empowers you to efficiently manage and monitor your heat trace circuits, reduce energy waste, and gain deeper insights into their performance.

-

Download Controller Statistics: Users can access and download detailed controller statistics for analysis. Simply click the (screenshot) icon to initiate the download of statistical data. This feature allows you to gather insights, track trends, and maintain records for your heat trace circuits effortlessly.

-

Wasted Power Calculation: ATCOM+ automatically calculates wasted power whenever a heat trace circuit is energized outside its regular schedule. This includes instances where a circuit is forced on or the maintenance temperature is increased. This valuable metric helps you identify and mitigate excessive energy consumption, contributing to cost savings and environmental sustainability.

-

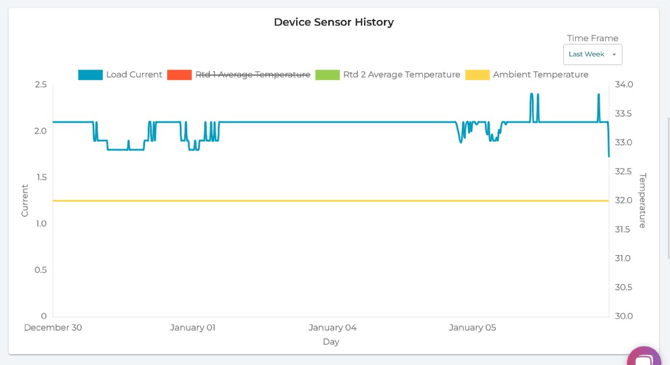

Sensor History and Trend Data: The "Sensor History" section presents trend data for your heat trace circuit. Users can interact with this graphical representation by clicking on trend titles to hide or show specific data on the graph. This feature enhances your ability to visualize and analyze temperature trends, enabling you to make informed decisions and optimize heat trace performance.

Audit Trail:

-

Comprehensive Programming Log: The Audit Trail feature in ATCOM+ serves as a comprehensive programming log. It meticulously records all programming modifications that occur within the system. Whether changes are made by a ATCOM+ user or directly at the physical heat trace device, every adjustment is meticulously logged.

-

User Accountability: The Audit Trail provides a transparent view of user interactions with the heat trace controllers. It clearly identifies which user initiated specific programming changes, enabling accountability and traceability within your heat trace management system.

-

Verification of Changes: This feature is invaluable for verifying any alterations made to the heat trace controller settings. It helps ensure that controller configurations align with the desired parameters and design criteria for each circuit

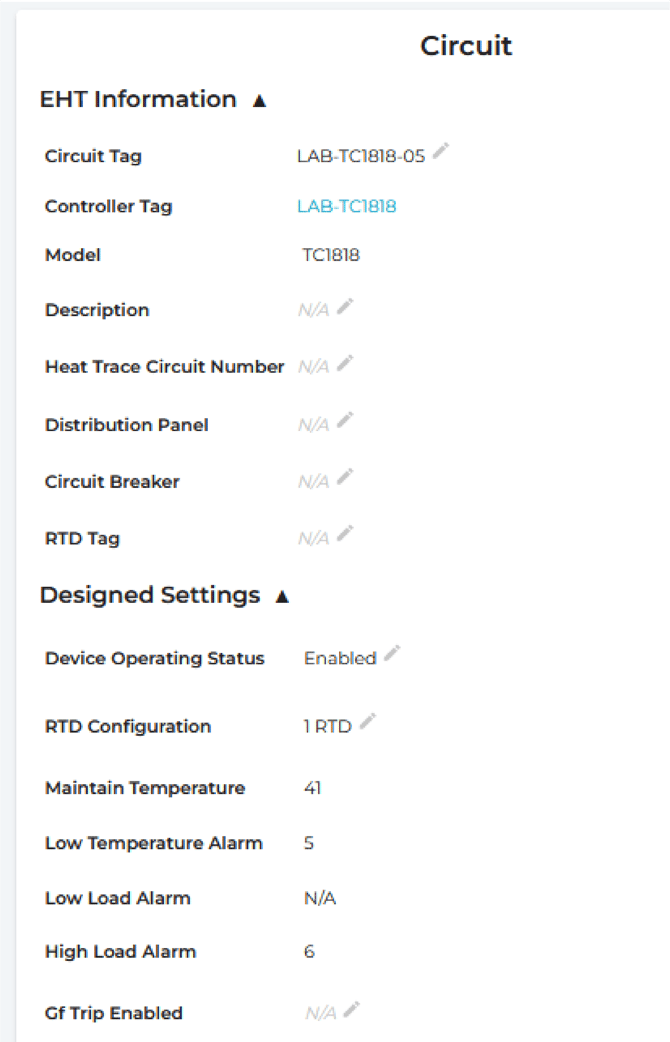

Controller Information:

-

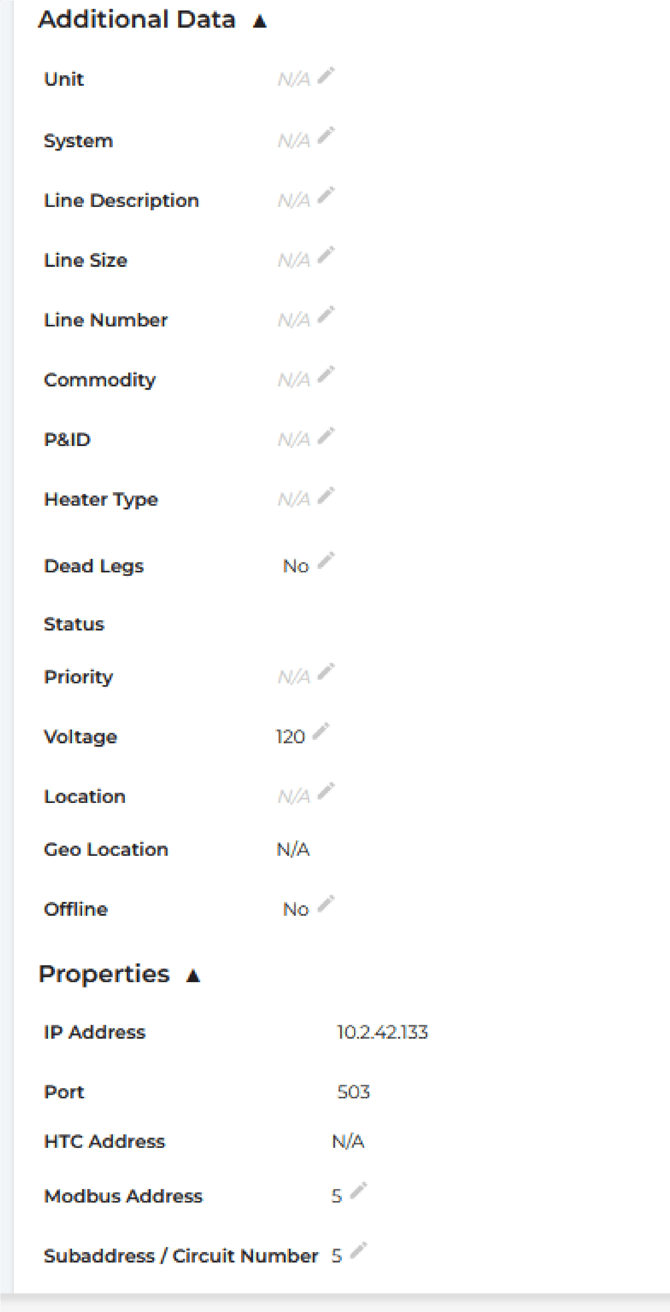

Circuit Details: On the left side of the display, you'll find comprehensive information about the heat trace controller. This includes data such as the circuit's identification, location, and a summary of its electrical specifications.

-

Process Information: ATCOM+ provides insights into the process being maintained by the heat tracing system. You can easily access data related to the piping or equipment that the heat tracing is protecting. This information aids in better understanding the context and purpose of each circuit.

-

Design Settings: Users can view the primary design settings of the controller. This includes the desired temperature maintenance values, alarm thresholds, and other critical parameters specific to the circuit's intended operation.

-

Document Control Center: ATCOM+ offers a Document Control Center that allows you to associate important drawings or documents with each circuit. This feature helps in maintaining a centralized repository for essential documentation related to the circuit, facilitating streamlined access for reference and maintenance purposes.

|

|

|

|

|

Advanced Features:

-

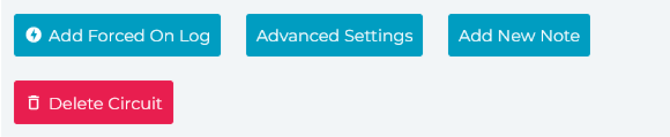

Forced On Circuits: Within this section, users can manage circuits that have been manually forced on or energized beyond their typical operating parameters. You have the ability to log circuits as "forced on" or make adjustments as needed.

-

Advanced Controller Settings: This is where more advanced controller configurations can be modified. Users with the appropriate permissions can fine-tune the controller's settings to align with specific operational requirements.

-

Circuit Notes: Users can also record circuit-specific notes, including information related to nuisance alarms, Lockout-Tagout (LOTO) procedures, or general notes. These notes provide additional context and documentation for each circuit's status and history.

ATCOM+'s Controller Information and Advanced Features sections serve as essential tools for managing and customizing your heat trace circuits efficiently. If you have further inquiries or need assistance with any of these features, please don't hesitate to reach out to our support team.