Efficient Alarm Management with ATCOM+: A Guide to Alarm Validation

Optimizing Alarm Handling and Work Tickets Integration for Seamless Heat Trace Management

Background:

ATCOM+ offers robust management features tailored to efficiently oversee heat tracing systems. The Alarm Validation section within ATCOM+ plays a crucial role in this, offering users a streamlined process to manage incoming alarms effectively.

Here's how it works:

- When new alarms arise, ATCOM+ prioritizes them based on custom criticality rule sets defined by the user.

- Alarms undergo filtering processes, first by checking for any open work tickets in the client's scheduling system (if integrated). Next, they are filtered based on valid nuisance alarms and circuit-related LOTO statuses (for specific alarm types).

- The result is an organized alarm list, indicating the presence of alarms, their criticality, and whether they require attention outside of ATCOM+'s scope.

Users can then take appropriate actions based on the alarm details presented.

Scheduling System Integration Overview:

Before diving into the step-by-step guide, it's essential to understand the integration of scheduling data into ATCOM+. While ATCOM+ currently lacks a direct API integration with scheduling systems (though one is in development), users typically leverage platforms like SAP or Maximo.

Here's the basic workflow:

- When work tickets are generated, users must link heat trace circuits to them, typically by pasting ATCOM+ circuit tags into designated fields in the scheduling system.

- Periodically, usually daily, users export predetermined reports from the scheduling system and import them into ATCOM+. This action syncs up open and closed work tickets in ATCOM+, ensuring accurate alarm validation.

- This integration is critical for ATCOM+ to differentiate between open and closed work tickets, ensuring alarms are appropriately displayed in the Validation Screen.

This integration streamlines the process and provides users with a comprehensive view of circuit history and information within ATCOM+.

Validating Alarms Step-by-Step:

The first step in the alarm validation process is to see if the client's scheduling system (if integrated) has any open work tickets. They are then further filtered according to legitimate nuisance alarms and, for some types of alarm, circuit-related LOTO statuses. You will find all alarms under the Alarm List.

1. Finding the Alarm List

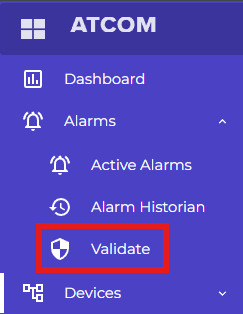

Navigate to the "🔔Alarms"- "Validate" section in ATCOM+.

2. Alarm List

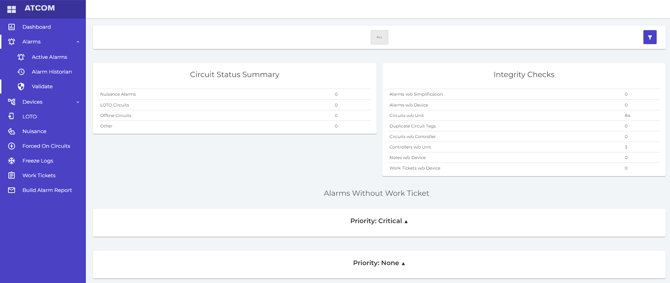

Entering "Validate" will bring you to ATCOM+'s organized alarm list, indicating the presence of alarms, their criticality, and whether they require attention outside of ATCOM+'s scope.

3. Alarm Information

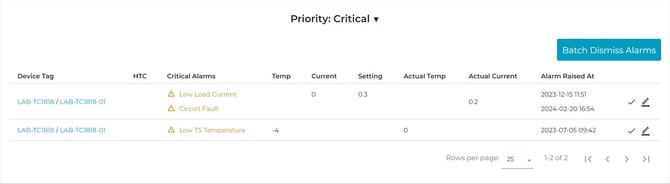

Accessing the "Priority: Critical" and "Priority: None" dropdowns will display customized alarms based on the user-defined rule sets.

An extensive explanation of the alert together with shared identifiers will show up, giving the user a clear picture of what set it off.

4. Alarm Actions

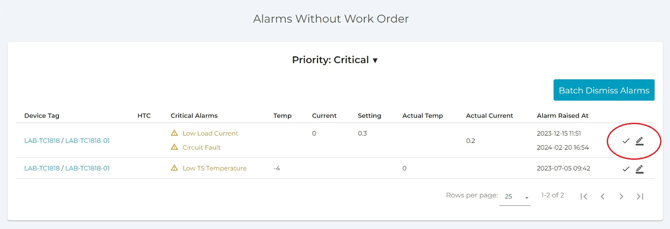

Every alarm will have two alternatives. You can enter "Valid Alarm(s)" by clicking the checkmark, or "Add Note" by clicking the underlined pencil, circled in red below.

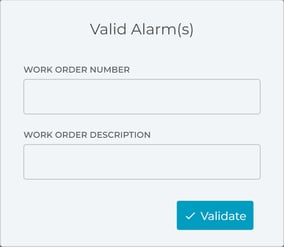

a. Valid Alarm(s): Users can submit a work Tickets number and work tickets description to technicians in the field for service through Valid Alarm. In order to ensure that work tickets are monitored in both ATCOM+ and the user's SAP, the user will utilize the work tickets number and description to link the ATCOM+ data to their SAP, depending on whether or not they are using one.

Look for the green confirmation bar in the top right to confirm work tickets has been Placed.

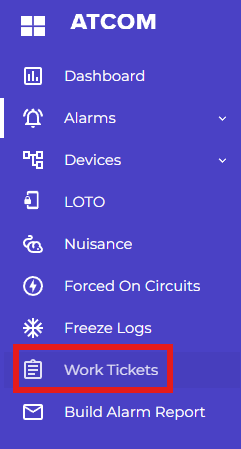

The "Work Tickets" tab on the left-hand navigation menu contains a list of all work tickets along with descriptions for each one. (Work Tickets is also helpful tool for locating any alarms in the user's system)

Tip: At the top of most ATCOM+ windows, you'll notice a filter bar. This allows you to quickly filter information by facility area. For more advanced filtering options, click the blue filter icon.

b. Add Note: users will have 3 Options

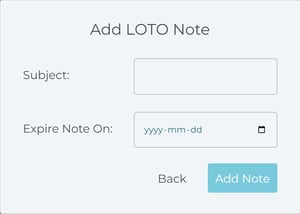

LOTO(Lock-Out Tag-Out): By selecting this option, users can ensure that dangerous machines are properly shut off and not able to be started up again before maintenance or servicing work is completed. It involves placing locks and tags on the energy-isolating devices of the machines to prevent them from being turned on inadvertently. This prevents accidental start-up and protects workers from injury caused by unexpected machine activation.

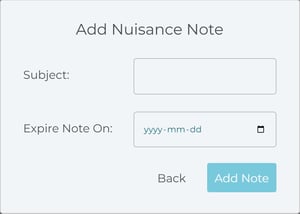

Nuisance: Users can resolve the alarm as a nuisance by choosing this option, which involves taking it off the list and designating it as such. (Technicians should still be sent to make sure the alarm was a false positive and doesn't need further action.)

Reset Alarm: While this function is useful for determining whether the alarm is active , users should exercise caution when utilizing it (button). By choosing this option, customers can reset the alarm and see if it resurfaces in real time troubleshooting. But this can lead to problems because alarms can originate from time-specific events—for example, a low temperature alert that only sounds at night. It is recommended for users to check alarms that have been reset and to ensure that no additional action is required. (A device may take up to an hour to report the same error.)

5. Resolving Alarms :

Creating Work Tickets Notes: The user will be prompted to complete a note with further information about the alarm and an expiry date for the alarm.

The alarm type and the affected circuit/controller are nearly always included in the subject line.

The Expiry date is determined by the user and is usually determined by the alarm type. For example, a LOTO could be initiated as a well is being redrilled. In this case the user would set the expiry date for the expected finished drilling date(or a couple days after). In contrast a nuisance alarm for Low Load might be set to expire in 2 days (so that the user can rereview it ?)

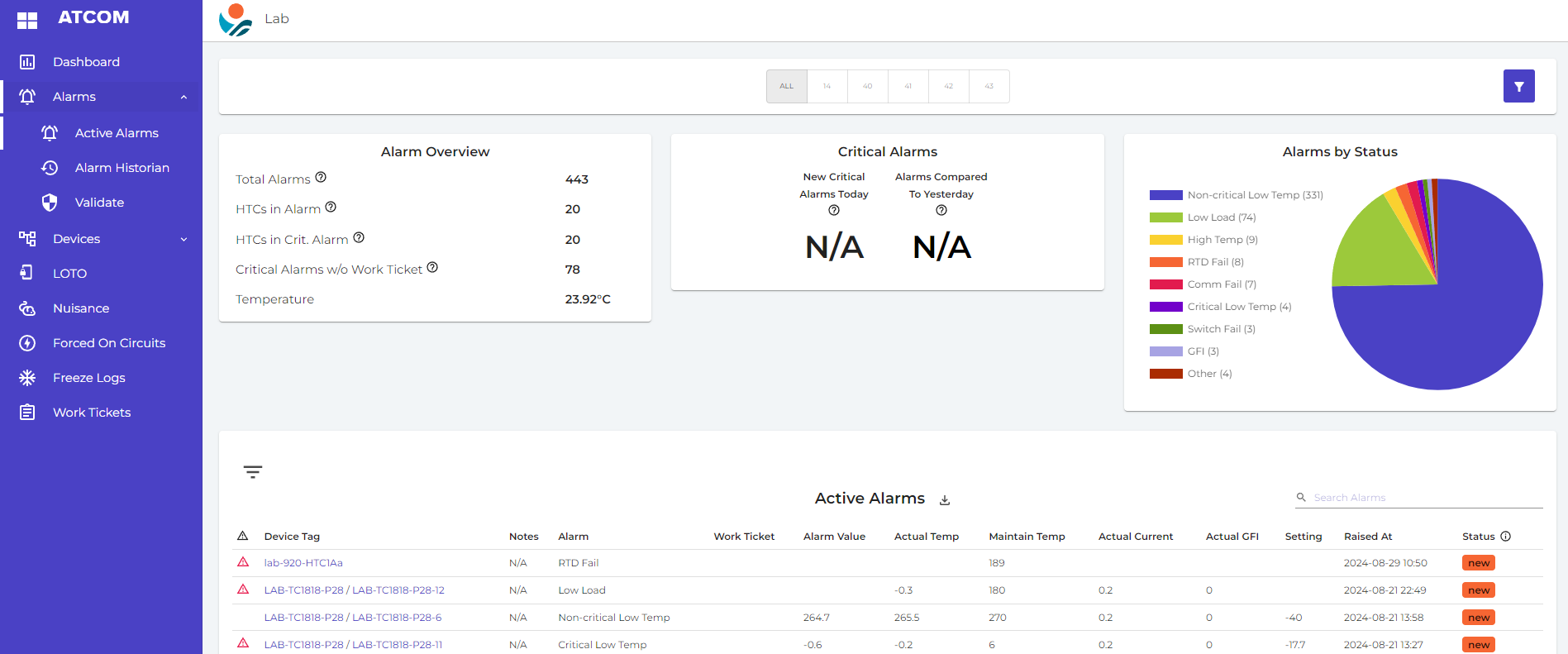

Active Alarms:

The "Active Alarms" tab offers a fantastic visual summary of all the active alarms in the user's system(( circuit, controller ,panel?)) together with real-time data on the intensity of the alarms, the number of new alarms as of today as opposed to yesterday, along with details on work tickets.

Tip: Alarms that may have gotten past criticality restrictions or logic can be located by using filters here.

ATCOM+'s Alarm Validation feature offers a comprehensive solution for managing heat tracing system alarms efficiently. By prioritizing alarms based on custom rule sets and integrating with scheduling systems like SAP or Maximo, users can streamline the validation process and ensure accurate representation of alarm statuses. Now that you have a firm grasp of the procedure and the resources at your disposal, you too can improve operational safety and efficiency while successfully maintaining the functioning and integrity of your heat tracing systems.